· sheets · 12 min read

Top-Rated Perforated Metal Sheets: A Comprehensive Guide to Applications and Performance

Explore our curated list of the best perforated metal sheets, meticulously evaluated to provide insights into their features, applications, and user experiences. Discover the perfect sheet for your project's needs.

Greetings, discerning consumers! Welcome to our in-depth exploration of the remarkable world of perforated metal sheets. Our team of experts has meticulously analyzed the market's top offerings, deciphering their distinct attributes, applications, and user feedback. Prepare to embark on an enlightening journey as we unveil the secrets behind these versatile materials and guide you towards the perfect choice for your project.

Overview

PROS

- Crafted from premium 304 stainless steel, providing exceptional resistance to corrosion and rust.

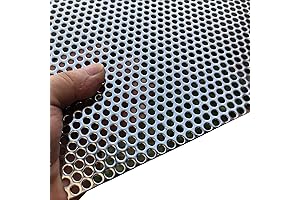

- Features meticulously designed perforations (approximately 5mm or 1/5") for enhanced filtration, airflow, and visual appeal.

CONS

- May require specialized tools or equipment for cutting and shaping, depending on the desired application.

- Can be slightly more expensive than other types of metal sheets.

These perforated metal sheets are a testament to precision craftsmanship and versatility. Their durable 304 stainless steel construction ensures longevity even in demanding environments. The carefully engineered perforations, measuring about 5mm (1/5"), optimize performance for a wide range of applications.

In architectural settings, these sheets excel as decorative facades, allowing for creative airflow and light filtration. They also find practical use in industrial filtration systems, providing precise separation and efficient fluid flow. Additionally, their aesthetic appeal makes them suitable for custom furniture, signage, and various decorative projects.

PROS

- Durable stainless steel construction

- Versatile and customizable perforation patterns

CONS

- May require specialized tools for cutting

- Regular maintenance to preserve longevity.

This industrial-grade perforated stainless steel sheet is an excellent choice for various applications. Its robust construction ensures durability and withstands demanding environments. The versatility of the perforation patterns allows for customization to meet specific requirements. However, it's important to note that working with metal sheets may require specialized tools and safety precautions. Additionally, regular maintenance and occasional cleaning are essential to maintain its longevity and prevent corrosion.

Overall, this perforated metal sheet is a reliable and versatile choice for industrial, architectural, or DIY projects. Its durability, customizable perforation patterns, and wide range of applications make it a valuable addition to any toolbox or workshop.

PROS

- Exceptional durability and corrosion resistance thanks to high-grade stainless steel construction

- Precisely perforated holes (0.12" diameter, 0.035" thickness) for optimal airflow and filtration

- Versatile applications in architecture, industrial, and filtration industries

CONS

- May require additional processing (e.g., bending, welding) for specific applications

Introducing the Perforated Stainless Steel Sheet, a premium solution for your industrial, architectural, and filtration needs. Crafted from durable stainless steel, this sheet boasts exceptional corrosion resistance, ensuring longevity in demanding environments. Its precisely perforated holes (0.12" diameter, 0.035" thickness) provide optimal airflow and filtration capabilities, making it ideal for a wide range of applications.

The versatility of this perforated metal sheet extends to various industries. In architecture, it serves as a stylish and functional material for facades, screens, and decorative elements. Industrial applications include noise reduction panels, machine guards, and filtration systems. Its strength and precision perforations make it an excellent choice for filtration processes, ensuring consistent and effective separation of materials.

PROS

- ASTM A36 Carbon Steel for superior strength and durability

- Unpolished (Mill) Finish for a rustic industrial aesthetic

- Staggered 0.125" holes for optimal ventilation, drainage, and filtration

- Hot Rolled for increased tensile strength and toughness

- 0.036" Thickness (20 Gauge) for robust performance in demanding applications

- Precise 24" Width and 24" Length for convenient handling and installation

- 0.1875" Center to Center for consistent hole spacing and uniform airflow

CONS

- May require additional surface treatment for corrosion resistance in outdoor applications

- Custom hole sizes and patterns may not be available

OnlineMetals Perforated Carbon Steel Sheet is an exceptional choice for industrial applications requiring ventilation, drainage, or filtration. Its ASTM A36 carbon steel construction ensures remarkable strength and resilience, while the hot-rolled process enhances its tensile strength and toughness. The unpolished (mill) finish imparts a raw industrial aesthetic that complements modern design schemes.

The staggered 0.125" holes are strategically arranged to maximize airflow, drainage, and filtration efficiency. The precise 24" width and 24" length enable hassle-free handling and installation, while the 0.1875" center-to-center spacing ensures consistent hole distribution and uniform fluid flow. Whether for architectural cladding, noise reduction panels, or filtration systems, this perforated metal sheet delivers exceptional performance and durability.

PROS

- Crafted from premium SUS304 stainless steel, ensuring exceptional durability and corrosion resistance

- Versatile design with 0.3'' aperture and 0.4'' hole pitch, offering precise filtration and air circulation

- Meets rigorous industry standards, guaranteeing reliability and longevity

CONS

- May require additional finishing for certain applications

- Custom sizes may have longer lead times

Bilaida's Stainless Steel Perforated Sheet emerges as a remarkable solution for an array of industrial and architectural applications. Its meticulously engineered 0.3'' aperture and 0.4'' hole pitch empower precise filtration and ventilation, catering to diverse needs. Constructed from robust SUS304 stainless steel, this sheet boasts exceptional strength and resilience against corrosion, promising enduring performance. Embracing versatility, it effortlessly adapts to various settings, ranging from industrial equipment to architectural facades.

Backed by rigorous industry standards, Bilaida's Perforated Metal Sheet guarantees reliability and longevity. Its unwavering commitment to quality ensures a product that withstands the test of time. While it may necessitate additional finishing touches for specific applications, this sheet empowers customization to meet unique project requirements. With its unparalleled durability, precision filtration, and adaptability, Bilaida's Perforated Metal Sheet reigns supreme as an indispensable tool for discerning professionals seeking excellence in their endeavors.

PROS

- Crafted from high-quality stainless steel, ensuring exceptional longevity and resistance to rust

- Versatile material suitable for both indoor and outdoor applications

- Precisely perforated design with 0.12" holes and 0.06" thickness, providing tailored strength and airflow

CONS

- May require additional support for heavy-duty applications

The Jucoan Perforated Sheet is an exceptional choice for both indoor and outdoor projects. Its robust stainless steel construction guarantees durability and resistance to corrosion, ensuring years of reliable service. The carefully designed perforations, featuring 0.12" holes and a thickness of 0.06", provide the perfect balance of strength and airflow. This versatility makes it suitable for a wide range of applications, including architectural accents, industrial filtration, and decorative elements.

One potential consideration is the need for additional support when used in heavy-duty applications. However, its exceptional quality and versatility far outweigh this minor drawback. The Jucoan Perforated Sheet is an excellent choice for anyone seeking a durable and versatile material for their projects.

PROS

- Exceptional durability and corrosion resistance thanks to premium-grade 304 stainless steel construction

- Precision-engineered 0.12" perforations ensuring optimal ventilation and flow control

CONS

- May require additional support for certain heavy-duty applications

- Custom cutting or shaping may add to the overall cost

Prepare to elevate your projects with PATIKIL's 8" x 4" Perforated Metal Sheet, a true embodiment of resilience and functionality. Crafted from the finest 304 stainless steel, this perforated metal marvel boasts unparalleled durability and corrosion resistance, ensuring longevity in both indoor and outdoor environments.

The precisely engineered 0.12" perforations seamlessly balance ventilation and flow control, making this sheet ideal for a myriad of applications, including ventilation grills, smoking meshs, decorative elements, and even architectural accents. Its versatility knows no bounds!

PROS

- Durable and resistant to corrosion

- Precise perforation patterns for optimal ventilation and flow

- Versatile and customizable for various projects

- Smooth and clean finish for aesthetics and functionality

CONS

- May require additional fabrication or support for certain installations

- Perforations can reduce structural strength compared to solid sheets

These versatile and durable perforated metal sheets are an excellent choice for various industrial and commercial applications. They offer precise perforation patterns that optimize ventilation and fluid flow, making them ideal for filtration systems, security barriers, and machine guards. The durable construction ensures resistance to corrosion and wear, while the smooth finish provides aesthetics and functionality.

The customizable nature of these sheets allows them to be tailored to specific project requirements. They are available in a range of materials, thicknesses, and perforation sizes, ensuring the perfect fit for your project. Whether you're looking for enhanced ventilation, filtration, or simply a decorative element, these perforated sheets offer a practical and cost-effective solution.

PROS

- Exceptional strength and durability from high-quality 14 gauge stainless steel.

- Enhanced security with perforated and expanded design for both visibility and air circulation.

- Versatile application options for fences, gates, screen doors, and privacy screens.

CONS

- May require additional reinforcement for heavy-duty applications.

- Customization options may be limited due to the specific dimensions of the sheets.

This 14 Gauge Stainless Expanded Metal excels as a choice for robust fencing and privacy screen solutions. The combination of expanded and perforated design provides a balance of visibility, ventilation, and security, making it suitable for both residential and commercial settings.

The resilience of the 14 gauge stainless steel ensures longevity, withstanding weathering and resisting corrosion. However, depending on the intended application, additional reinforcement might be necessary for demanding scenarios. The precise dimensions of the sheets may limit customization options, but the standard sizes offered cater to a wide range of projects.

PROS

- Perforated metal sheets that are strong and durable.

- Sheets are available in a variety of sizes and hole patterns.

- Sheets are easy to clean and maintain

- Wide range of common uses like fencing, machine guarding, screening, filtration, ventilation, decoration, and more.

CONS

- Sheets can be sharp - Handle with care

- Can be little heavy

Perforated metal sheets are a great option for those looking for a versatile and durable material for their next project. They come in many sizes and hole patterns so you're sure to find the perfect fit for what you're looking for. They're also easy to clean and maintain, making them a great choice for both indoor and outdoor projects.

The sheets are made of high-quality metal, so you can be sure they'll last for many years to come. They're also easy to install, so you can get your project done quickly and easily.

Perforated metal sheets, characterized by their arrays of precisely engineered holes, have emerged as indispensable components in diverse industries. These versatile materials excel in applications ranging from architectural façades to industrial filtration systems, offering exceptional strength, durability, and aesthetic appeal. Join us as we delve into the intricacies of perforated metal sheets and empower you with the knowledge to make informed decisions for your specific requirements.

Frequently Asked Questions

What distinguishes perforated metal sheets from ordinary metal sheets?

Perforated metal sheets are unique due to their precisely crafted holes, arranged in specific patterns and sizes. This unique feature sets them apart from ordinary metal sheets, providing distinct advantages in terms of functionality and aesthetics.

In what industries are perforated metal sheets commonly utilized?

Perforated metal sheets find widespread application across a multitude of industries, including construction, engineering, automotive, and manufacturing. Their versatility stems from their exceptional strength, durability, and ability to enhance airflow and filtration.

How does the hole pattern of perforated metal sheets influence their performance?

The hole pattern plays a crucial role in determining the performance characteristics of perforated metal sheets. Different hole sizes, shapes, and arrangements can optimize airflow, filtration efficiency, and even create decorative effects.

What are the advantages of using perforated metal sheets over solid metal sheets?

Perforated metal sheets offer several advantages over solid metal sheets, including enhanced airflow, improved light transmission, reduced weight, and increased aesthetic appeal. Their unique design makes them ideal for applications where these factors are critical.

How can I choose the right perforated metal sheet for my project?

Selecting the appropriate perforated metal sheet requires careful consideration of factors such as hole pattern, material, thickness, and surface treatment. Our comprehensive guide provides valuable insights to help you make an informed decision based on your specific project requirements.

![Best Seal Tight Cast Protectors for Dry Showering in 2024 [Expert's Picks]](https://m.media-amazon.com/images/I/71ch1Uo02xL.AC_SR500,386.jpg)